Use the guillotine to cut the aluminium sheet to the size what you want.

Step 2:

Use the cylindrical wood as template to bend the aluminum sheet, give it a initial circular shape.

Step 3:

Use round plastic hammer to hit the mid part of the sheet, shape it to a concave shape (hit the sheet uniformly, keep the curving shape of the sheet.)

Keep hitting until the whole mid part of sheet is concave (shows in next picture)

Step 4:

This is the time to make the two sides of sheet concave. First, use hammer to hit the side of this curve part, make it curve upward. ( use hand to hold the sheet stand, this will be easy to concave this part)

Give an initial curve shape of the sheet and do next step.

Step 5: Refine the reverse curve.

After defined all the parts of the sheet, use a polishing hammer with a rounds metal stand to make the curve part more accurate and smooth.Carefully stretch and shape the metal, to stretch this element until there is a perfect fit.

Step 6:

Use a polishing hammer to hit the sheet lightly, in order to get rid of any unwanted creases and scratches.Use the english wheel to make it smooth.

Final Step:

Use the Brasso to polish the aluminium sheet.

Reflection

|

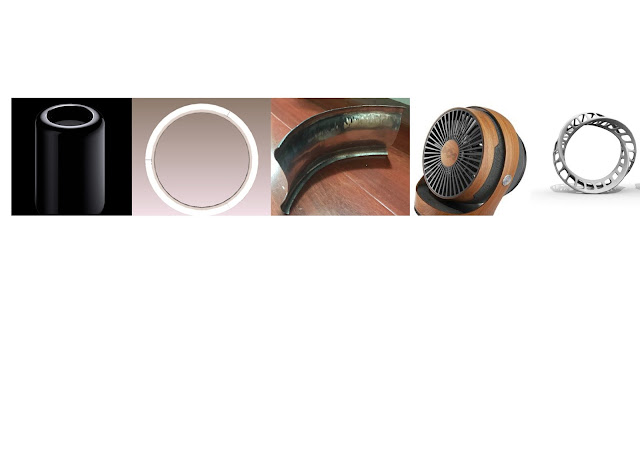

| Industrial design related to my work |

|

| Architecture form related to my work |

评论

发表评论